myspace

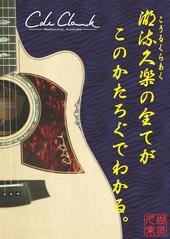

.. ..Cole Clark guitars combine classical construction with innovative design and manufacturing techniques to produce lighter, stronger instruments with superior acoustic performance. Made using indigenous timber and featuring Face Brace Sensor acoustic pickup systems, Cole Clark guitars provide professional quality at affordable prices.Check out the range of FAT LADY acoustic dreadnaughts. This range consists of the basic FATLADY1 ( FL1) up to the deluxe FATLADY3 ( FL3).FL2"At Cole Clark Guitars, we've applied a new understanding to an age old art. Like you, we appreciate the sound and feel of a great steel string guitar, one that reflects and projects the emotion you put into your music. Great guitars require great tone woods, and we select our timbers with care. Even our most basic model acoustic is made from all solid timbers. Our patented manufacturing method applies the finest of control to each instrument we make, so that every instrument can be loud and lively and subtle and soft. The Cole Clark Fat Lady is a truly awesome sounding instrument. It whispers, it yells and it sings, and you know that your search for the perfect acoustic guitar isn’t over... ‘til the Fat Lady sings!FL1At Cole Clark Guitars we precision manufacture guitars to provide the optimum in sound quality and playability. The fact that we use modern technology should not be mistaken for a lack of respect for past methods. Acoustic guitar making remained relatively unchanged from the mid 1850’s Martin “X†braced design until now. The original “X†was modified in the early 20th century to accommodate steel strings, and the “14 frets clear of the body†design to give greater fret access arrived just prior to 1930. From then, not much changed. There have been a few excursions into alternate materials, “space age†laminates, odd shapes etc., but mostly acoustic steel string guitars have been made the same way for a long time. Players agree that timber is the material that sounds best, and timber is our medium We combine the benefits of an integral neck heel with an accurately tuned face and back for exceptional clarity and sustain. The integral neck heel, while held in high esteem, has always been difficult to produce well, which is why most manufacturers opt for the more accessible but less efficient dovetail joint, screws or dowels, all of which are more at home in the furniture industry. Our ability to accurately make the integral neck heel enables us to manufacture with incredibly tight tolerances and this allows accurate assembly of our instruments. The violin makers of history understood the necessity of tuning the vibrating plates of an instrument ( the top and the back ). We carve our tops and backs to achieve the best possible sound, using CNC router technology for extreme accuracy. The results are instruments which perform like no others."FL3MistressStealthCulpritJack JohnsonPete Murray & MayerSnow Patrol